Video

Picture

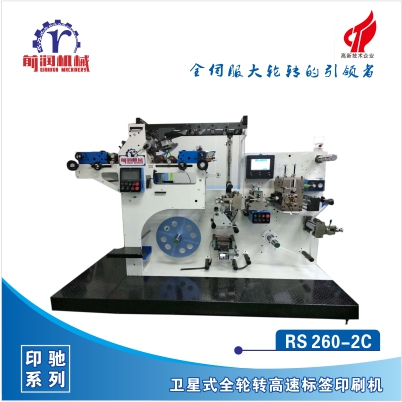

高精度中心壓筒設計保證了印刷套準精度,結構緊湊,操作方便。全伺服自動控制進一步提升了機器的套準精度、工藝的靈活性及承印物的多元化。機器運轉(zhuǎn)或停機時,可進行套準調(diào)節(jié),優(yōu)異的套準精度,無級調(diào)節(jié)的長度套準,各工作位置的橫向套準可以±5毫米進行調(diào)節(jié)。本機可完成工藝:多層標簽、正反面印刷10色任意組合、局部除膠、前后中全息定位冷燙、二次自動定位模切、連線覆轉(zhuǎn)印膜及無膠光膜。

Technology Parameters

| Model | RS260-10C+1F |

| Number of Printing Polor | 10 color embossed + flexo glazing |

| Max. Web Width(mm) | 260(10.25 inch) |

| Max. Printing Width(mm) | 254(10 inch) |

| Max Printing Length(mm) | 457.2 |

| Max Speed | 100m/min |

| Ink | UV off set ink/UV flexo ink |

| Centre Impression Drum | ø1300mm rubble-lined |

| Max. Dia of Unwind Roll | 800mm |

| Max. Dia of Rewind Roll | 800mm |

| Machine Size(L*W*H:m) | 7*1.8*2.25 |

| Net Weight(Kgs) | 9000 |

| Power(V/Kw) | 3phase 380V, 45KVA, 50/60HZ |

| Air Pressure | 0.6Mpa(6kgf/cm ) |

| Operation Noise | 〈85db |

Basic Information

| Function |

| Unwinder-Printing(10color, 2color printing on glue side,4color for both side)-gold stamp-Lamination-Die cuter-Waster- Rewinder |

| Standard Accessories |

| 1.Letter press print station |

| 2.Flexo varnish surface coating |

| 3.UV dryer |

| 4.Printing cylinder |

| 5.Egdes trimming device |

| 6.Rotary die cutter |

| 7.Corona theater |

| 8.Electrostatic eliminator |

| 9.Lamination |

| 10.Front cold stamping |

| 11.Waster device |

| 12.Back printing unit |

| 13.Glue side printing unit |

| Optional Configurations |

| 1.After cold stamping |

| 2.Static state observation system |

| 3.Cooling system |

| 4.Optional 2-22 color |

| 5.Digital printing for barcode |

| 6.Rotary screen printing device |

| Features |

| 1.Compared with common label printing machines, RS260-10C+1F can reach a high speed of 100M/min andl with more precise positioning and more accurate color printing. Advanced ink distribution ensures more even coloring. |

| 2.With both flatbed die cutting and rotary die cutting systems. |

| 3.Koldfoil stamping in the front, middle, back, and local or positioned stamping can be completed synchronously and quickly. |

| 4.Multi-color printing on backside can be realized by optional backside printing device. |

| 5.With function of spacer and local degumming, base paper stripping off, gelatinizing and sealing. |

| 6.HP inkjet technology is applied in bar code label designing. |

| 7.Optional inspection machine will feed and inspect labels automatically, which saves labor costs. |

| 8.With Corona surface processor. |

| Printing Materials |

| Adhesive Tape、Washing Mark、Art Paper、PET、PE、PVC、PP、Synthetic Paper、Protective Film、Pearlescent Film、Dumb Silver、Laser paper |

| Industry Appilcations |

| Cosmetic Label、Food Label, Water Label, Drug label, Electronic Label,Bar Code Label,Toy Label,PVC Label,Reverse Stickers |

| Customization |

| According to customer's requests, RS260 can be customized from 2 colors to 12 colors or other models like RS320, RS400, RS460 |